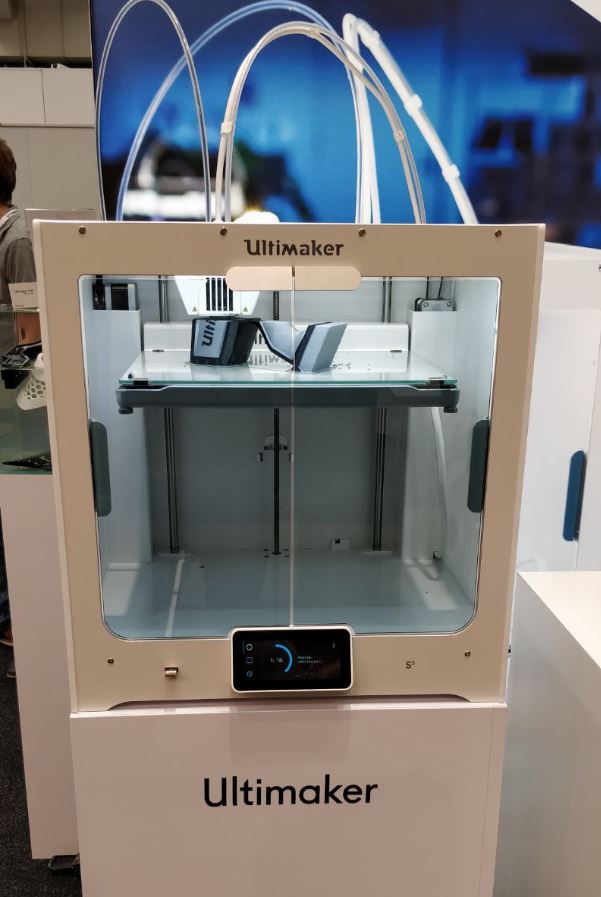

The Ultimaker S7 3D Printer is a new cutting edge device, that raises the bar in terms of features and results. Produced by one of the foremost 3D printer manufacturers, the Ultimaker S7 offers exceptional performance, accuracy and quality. The printer is easy to use and the touch-screen interface is intuitive, making it simple to start printing right away. The build volume of the S7 is generous, allowing you to print larger objects with ease. The automatic bed leveling system is a huge plus and ensures that every print is successful. The print quality is exceptional and the level of detail that can be achieved is highly impressive. The S7 also features a number of safety features, such as an enclosed build chamber and a HEPA filter, which makes it safe to use in any environment.

In terms of maintenance, the S7 is relatively low-maintenance. The print bed is easy to clean and the filament spool system makes changing filaments a breeze. The printer also features a filament run-out sensor, which eliminates the need for manual intervention and makes the printing process more seamless.

In conclusion, the Ultimaker S7 3D Printer is a fantastic 3D printer that offers outstanding performance and quality. Whether you’re an experienced maker or just starting out, this printer is a great investment that will provide you with endless creative possibilities. I highly recommend the S7 to anyone who’s looking for a reliable, high-quality 3D printer.

The Ultimaker S7 3D printer is available to purchase from Feb 22nd at Matterhackers for $8,299.